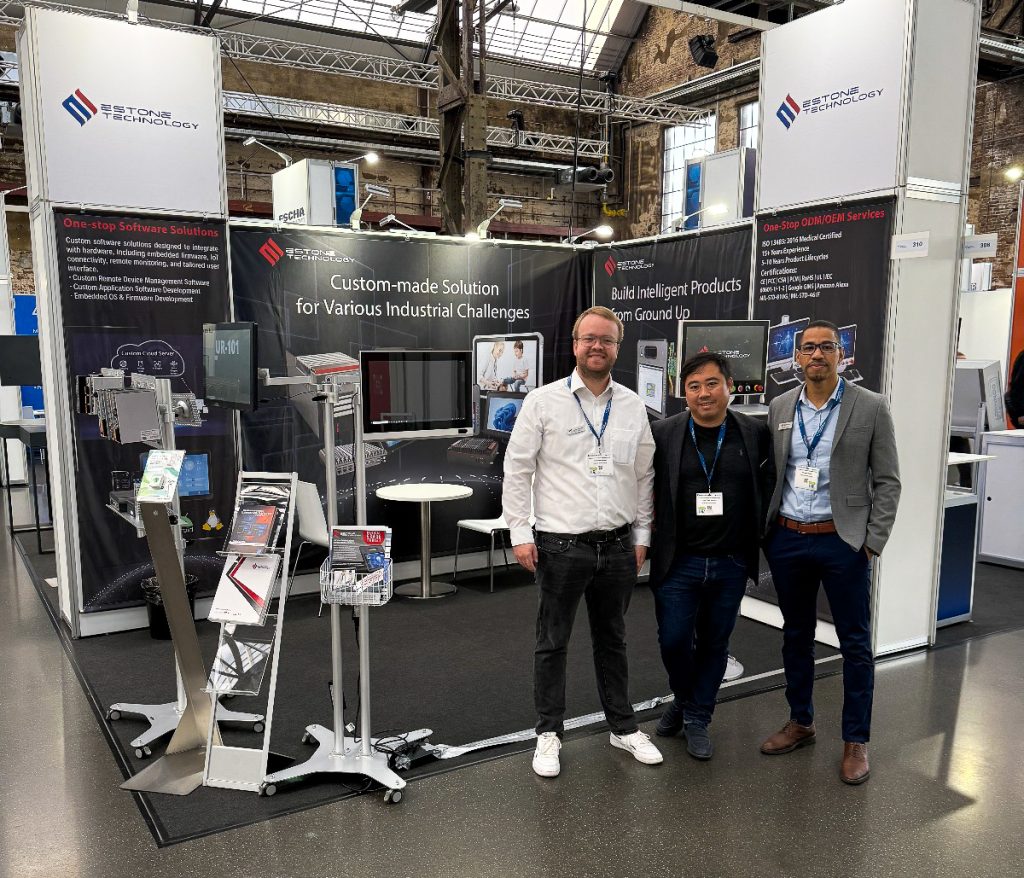

At AAA Düsseldorf the conversation was the same everywhere: push compute to the edge, make HMIs smarter and tougher, expect real-time deterministic controllers in compact form factors, and treat rugged mobile devices as first class automation tools. Estone’s ODM portfolio already maps to each of these trends. From box PCs and Panel PCs to automation controllers and rugged tablets, which makes us a practical partner for customers who want those capabilities built into their OEM products.

Operators expect consumer-grade touch and readability in harsh plants: high-brightness displays, capacitive multitouch, fanless and IP-rated fronts. Modern Panel PCs reduce integration time and improve operator UX.

At Estone we have our Industrial Panel PC series with fanless design, and front-IP rated (IP65). These Panel PCs support capacitive touch and offer flexible mounting and I/O for OEM integration. They are ideal for machine builders who need rugged, visually reliable HMIs that integrate into arms or enclosures.

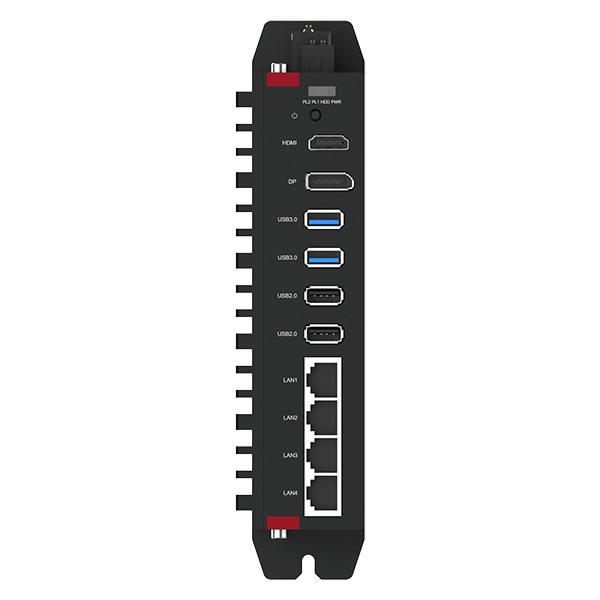

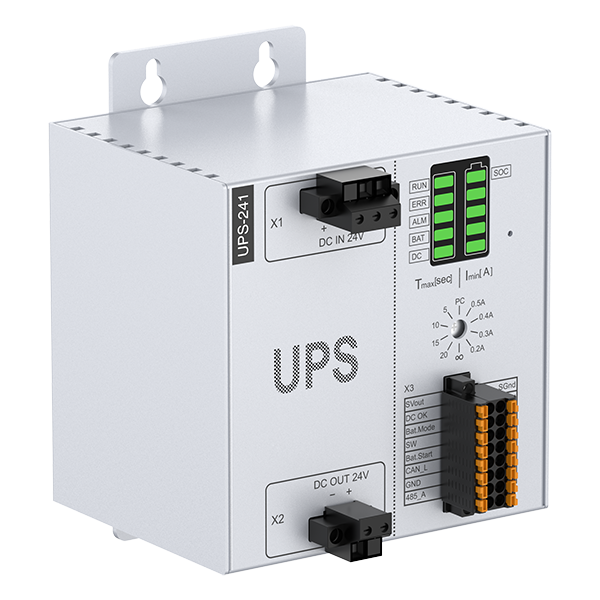

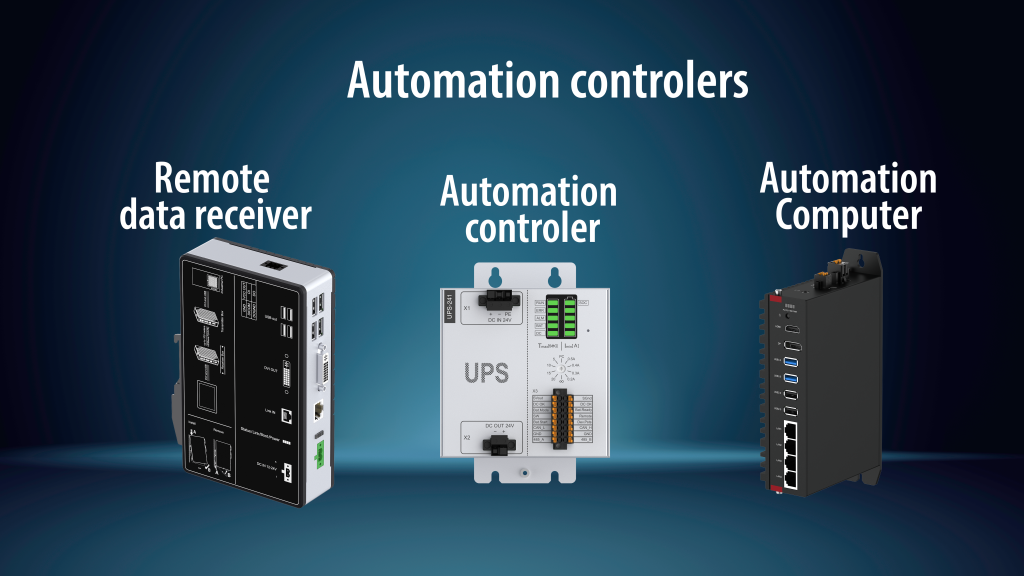

Machine designs demand smaller footprints without sacrificing real-time capabilities. DIN-rail controllers and compact cabinet PCs with native I/O and expansions (E-BUS/EtherCAT modules) are trending for modular machine architectures. Market demand for these controllers is strong. Practical tie-in might be to pair a DIN-rail for the motion loop and an Automation PC for supervisory tasks and HMI hosting. This keeps the control loop deterministic and your OEM design compact and maintainable.

Estone has automation PCs (APC-5712 is one of them) and DIN-rail iPAC controllers that offer EtherCAT, modular expansion, built-in DI/DO/RS-485 and supercapacitor UPS options, enabling true 24/7 deterministic control in tight spaces and as part of ODM machine solutions. These controllers are production-grade and designed for OEM lifecycle requirements.

Field service and warehouse operations demand mobile devices that survive drops, liquids and cleaning protocols, and, in medical use, devices must meet stricter certifications. Rugged tablets with hot-swappable batteries, optional barcode/NFC, and 4G/5G are trending in 2025.

Estone’s rugged tablet family, which includes MD-100, UR-100N, MW-100 and many more, is MIL-STD and IP rated, offers hot-swappable batteries, optional 4G/5G, barcode/NFC modules and medical-grade variants, built with ODM options so integrators can add modules (RFID, high-precision GNSS, custom housings) for specific workflows. Therefore, If customers need a disinfectable medical tablet with IEC/ISO certifications or a field tablet with barcode scanner and 5G, we already have the building blocks.

At AAA there were demos that moved vision and analytics from the cloud to the cabinet or machine, low latency, reduced cloud traffic, improved reliability for closed-loop control, predictive maintenance and inline vision/AI. In parallel, Industrial edge computing is explicitly described as a core growth area for automation in 2025. What this means for you is pick a box PC that supports NVMe for fast model loads, has expansion (M.2 for cellular / modem / accelerator modules) and has multiple GbE / 2.5GbE ports for camera lanes.

Estone’s Industrial Box PCs and AI computers are specified for edge workloads (including NVIDIA Jetson options and 12th-gen Intel CPUs), with M.2 NVMe, optional 5G/Wi-Fi modules and long life-cycle support, ready for inference, data pre-processing and gateway tasks inside the cabinet or at the machine. See the BPC series and AI computer notes.

A recurring conversation was: don’t throw away determinism when you add IIoT. Demand vendor-neutral, secure data exchange (OPC UA) plus real-time network tech for motion and deterministic I/O, manufacturers expect the stack to ‘just work’. OPC UA adoption and related connectivity trends continue to accelerate in 2025.

How Estone fits: Estone’s automation product lines support modern industrial interfaces and modular I/O. iPAC and DIN-rail controllers ship with EtherCAT and field I/O options suitable for real-time motion and distributed automation. That makes it straightforward to architect systems that use OPC UA for plant-wide telemetry while keeping deterministic control local.

At AAA Düsseldorf the talk was pragmatic: operators and integrators want solutions that can be dropped into production and supported for years. That’s the core of Estone’s offer: configurable hardware platforms (box PCs, panel PCs, rugged tablets) and proven automation controller partners that make OEM/ODM work risk-aware and repeatable.