As Industry 4.0 continues to revolutionize manufacturing, industrial control, and robotics, businesses require advanced Human-Machine Interface (HMI) solutions and embedded computing platforms that deliver real-time control, secure data communication, and seamless system integration. From factory automation to robotic control systems, modern industrial environments demand ruggedized, fanless industrial Panel PC solutions that ensure efficiency, reliability, and scalability in mission-critical applications.

Estone Technology provides cutting-edge industrial panel PCs and fanless embedded computers designed for edge computing, machine vision, AI inference, and industrial controls. The industrial automation solutions provide automation integrators and machine builders with the rugged computing platforms and HMI solutions. All needs to optimize system performance, enable intelligent automation, and ensure seamless machine-to-machine communication. To offer customizable hardware, real-time data processing, and long-term product, Estone help integrators and OEMs develop scalable, future-proof automation systems. Those solutions enhance efficiency, reduce downtime, and meet the evolving demands of industrial control and robotics applications.

Industrial automation solutions require ruggedized, fanless embedded computing solutions that can withstand dust, moisture, vibration, and extreme temperatures while ensuring 24/7 reliability in harsh environments. In addition to durability, real-time control and low-latency data processing are critical for precise machine operation, robotics, and industrial control systems. Traditional automation setups often struggle to keep up with these demands, making it essential to adopt PC and ARM-based industrial computers and HMIs with dedicated real-time computing and high-speed data processing capabilities.

In short, with the rise of Industry 4.0, manufacturers are integrating machine vision and AI-driven automation for predictive maintenance, defect detection, and intelligent decision-making. These applications require AI accelerators like Neural Processing Units (NPUs) to execute real-time inference and automation tasks efficiently. Consequently, seamless industrial communication remains a challenge, as factories rely on traditional RS-232, RS-485, CAN, Modbus, and Ethernet protocols. All the integration with modern IoT cloud systems can be complex. Above all, manufacturers require customizable industrial HMIs and embedded computers tailored to specific software, I/O, and mounting requirements, along with long-term hardware availability to ensure uninterrupted production and large-scale deployment. So, addressing these challenges is essential for achieving scalable, high-performance industrial automation solutions that enhance productivity and operational efficiency.

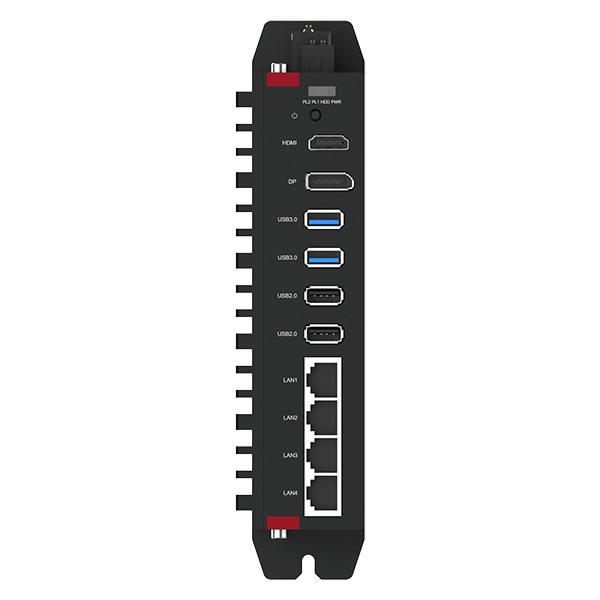

Estone’s compact, fanless embedded PCs provide high-performance computing, and secure connectivity for industrial automation, control cabinets, and IoT gateways.

● Rugged aluminum enclosures with DIN Rail mount for secure installation in factory control systems.

● Dual Gigabit Ethernet with optional Power over Ethernet (PoE) for simplified industrial networking.

PCIe expansion for AI acceleration, LTE modules, or additional I/O customization.

Products: PPC-CXX27 Series, PUC-CXX65 Series

Our industrial-grade panel PCs provide intuitive touchscreen interfaces for factory automation, robotics, and process monitoring.

● Multi-touch displays (12.1” to 21”) with IP65-rated front panels for industrial durability.

● Industrial solutions reduce cabling complexity for easy deployment in automation systems.

● Flxible mounting options (panel mount, wall mount, VESA) ensure seamless industrial integration.

Both reliable industrial communication and real-time control are essential for programmable logic controllers (PLCs), robotics, and factory automation systems.

● Support industrial protocols including RS-232, RS-485, CAN, Modbus, and GPIO for seamless system integration.

● Dedicated M4/M7 microcontrollers in i.MX8M processors provide real-time control for time-sensitive automation.

● Custom Linux OS configurations, for example, Yocto, Ubuntu, Qt, for optimized industrial automation software.

AI and machine vision technologies not only enhance automation efficiency by enabling predictive maintenance, but also defect detection, and real-time decision-making.

● Edge AI computing with integrated NPU for machine learning, object recognition, and industrial anomaly detection.

● AI-enabled edge computing with integrated NPU, TPU, or other AI accelerators for machine vision and AI-powered analytics.

Challenge: Prevent unplanned downtime and optimize factory operations.

Solution: The NPC-7112, powered by NVIDIA Jetson Orin Nano 4GB/8GB module, processes machine learning models for predictive maintenance, identifying potential failures before they occur. As a result, it reduces maintenance costs, increases equipment uptime, and enhances overall production efficiency.

Challenge: Manufacturers need rugged, real-time process monitoring systems that seamlessly integrate with industrial control networks.

Solution: The PPC-CXX27 Series provides 24VDC power, panel-mount HMIs with capacitive touchscreens and RS-485/Modbus connectivity, at the same time, ensuring seamless SCADA integration, real-time data visualization, and enhanced operator control.

Challenge: Robotic systems require low-latency, secure communication between controllers and actuators to ensure precise motion control and real-time decision-making.

Solution: The BPC-7611 offers CAN bus support, NPU dedicated for neural network inferencing, integrated real-time MCU control capabilities, as well as secure boot authentication, providing stable, secured communication for robotics automation, AGVs, and smart manufacturing systems.

Estone Technology specializes in tailor-made embedded computing and HMI solutions designed for industrial automation, robotics, and smart factory applications. Altogether our custom hardware and software solutions help automation integrators and machine builders to develop high-performance, seamlessly integrated systems that meet specific industry requirements. From custom I/O configurations supporting RS-232, RS-485, CAN, and GPIO to versatile mounting options such as panel mount, VESA mount, and DIN Rail, our solutions ensure flexible deployment in control cabinets, robotic enclosures, and factory automation systems. Additionally, we provide optimized OS and firmware services in Yocto Linux, Ubuntu, and Android environments, preloaded your industry-specific software for AI-driven machine vision, predictive maintenance, and automated quality control.

In summary, with long-term product lifecycle support backed by our longevity program, Estone Technology guarantees hardware availability for extended industrial deployments. So, it makes us the ideal partner for future-proof automation solutions. As shown above, our custom branding and customization services allow our customers to create market-ready, branded industrial computers and HMIs, complete with custom enclosures, preloaded software and firmware. To combine industrial-grade reliability, scalable customization options, and long-term product support together. At least, Estone Technology empowers automation OEMs and system integrators to develop high-performance, efficient, and reliable industrial computing solutions.