Know the IP protection class

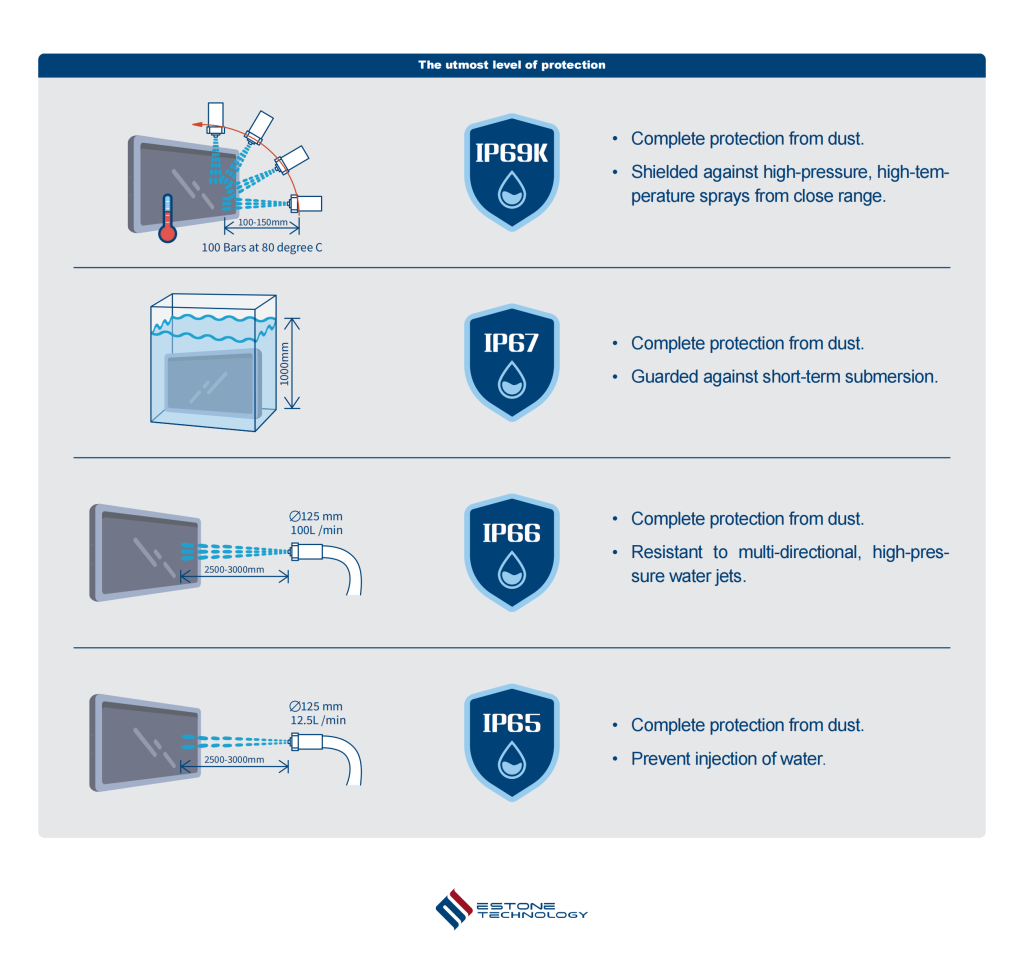

IP rating (Ingress Protection) is an important standard for evaluating the dust and water resistance of equipment. This standard is developed by the International Electrotechnical Commission (IEC) to provide a unified protection level assessment for electrical equipment. The first number in the IP code indicates the ability to protect against the entry of solid foreign objects, such as fingers or dust, and ranges from 0 to 6; The second number indicates protection against liquid intrusion and ranges from 0 to 9. See the chart in this article for details on what each rating means. When an “X” is used in place of the first or second number in an IP code, it indicates that the device has not been tested accordingly.

FAQ:

What is the significance of IP protection level testing?

IP protection level testing ensures that the equipment can operate properly in a specific environment. The tests verify that the equipment prevents dust, moisture, or other particulate matter from causing damage to internal components, thereby ensuring long-term stability and performance of the equipment. Protection requirements vary according to the characteristics of different products and environments in which they are used. The protective performance of the product shell must closely match the actual application scenario to better meet the use requirements.

Does the test sample need to be electrified during the IP protection class test?

The standard does not require the equipment to be tested with power on. If you need to simulate the actual use of the environment, it is possible to power the test, but you need to make sure that safety measures are taken during the test.

What is the IP5X dust entry standard?

IP5X allows dust to enter, but does not affect the safe operation and safety of the equipment, and IP6X can not find dust accumulation. In the case of IP5X dust entry, the standard only mentions that a certain amount of dust is allowed to enter, and does not give specific quantitative indicators and detection methods.

The larger the number of IP grade, does it mean that the waterproof effect is better?

In general, a larger number indicates better sealing of the device, but this does not mean that a product with an IP67 rating will necessarily meet the requirements of IP66 or IP65. In other words, just because a prototype meets the IP67 rating does not mean that it meets both the IP66 or IP65 rating standards. The reason is that the water gun of IPX5 and IPX6 has a water speed requirement, and the water pressure of the water gun is more permeable than the water pressure of the penetration bubble. This document also gives corresponding statements. If the product supports both the water gun and the penetration bubble, the corresponding grade should be marked at the same time, such as IPX6/IPX8. If only IPX8 means only immersion but not exposure to the spray gun, and if only IPX6 means only immersion but not immersion.

What is the difference between IPX9 and IPX9K?

The definition of IPX9 comes from IEC 60529, and the definition of IPX9K comes from ISO 20653. The IPX9 does not specify water pressure requirements, while the IPX9K does, where the “K” indicates that the test needs to meet additional pressurization requirements. For example, a test pressure of 10,000 kPa (100 Bars) is required for the IPX9K. Similarly, other protection classes with “K” (such as IPX4K and IPX6K) also have clear requirements for test pressure. IPX9K is more inclined to industrial and special field equipment, such as the automotive industry (engine, lights, etc.), industrial equipment, agricultural machinery, etc., especially the scene that needs to withstand high temperature and high pressure cleaning.

Tags: # waterproof grade, #IP standard science popularization, # dustproof grade, #IP, # waterproof and dustproof